| COIL TUBING / THRU-TUBING MOTOR DYNAMOMETER 1.6875" to 3.7500" Diameter Motors Pump Capacities to 126 gpm / 2100 psig Torque Capacities to 2000 lb-ft (Standard system, other rates and max. Pressures available) |

| SELF CONTAINED GEN-SET PUMP SYSTEM |

| DIESEL DRIVEN CLOSED LOOP HYDRAULIC PUMP SYSTEM |

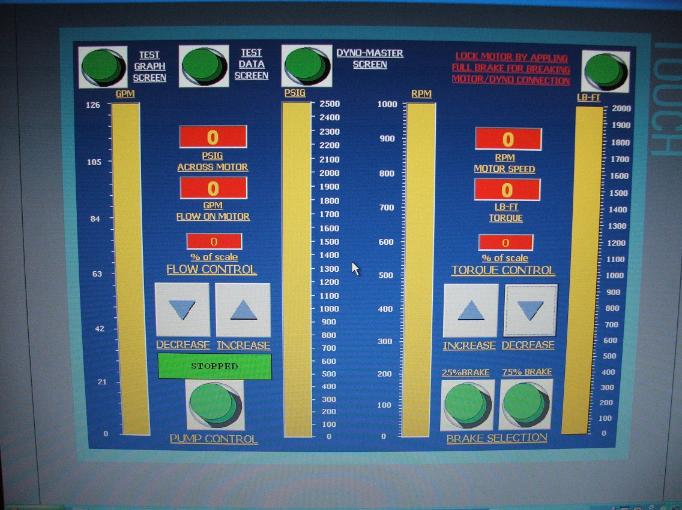

| Dyno-Master System Control Panel |

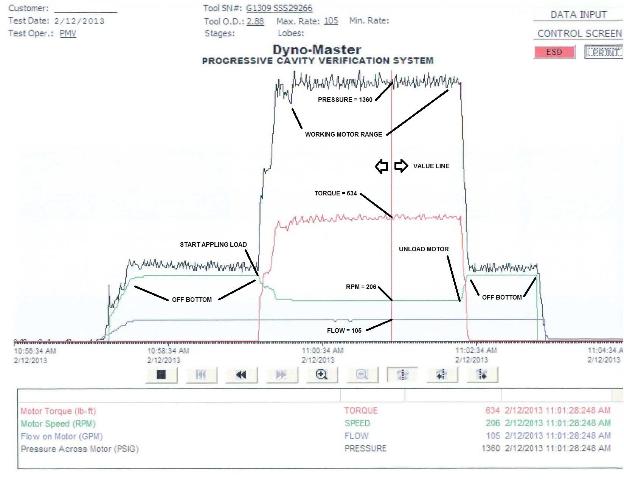

| Example of actual test graphic showing "Working" condition |

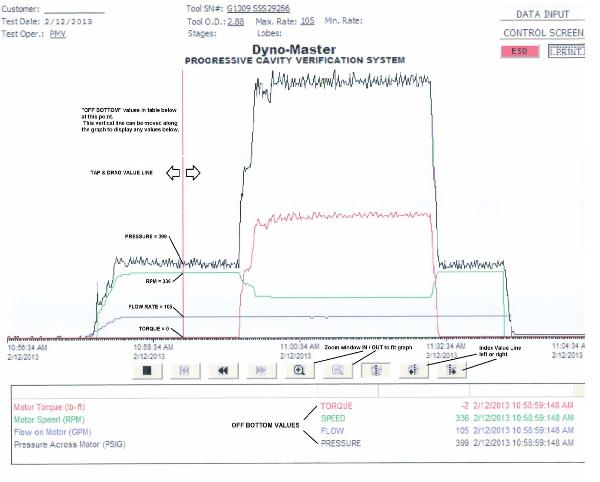

| Example of actual test graphic showing "Off-Bottom" condition |

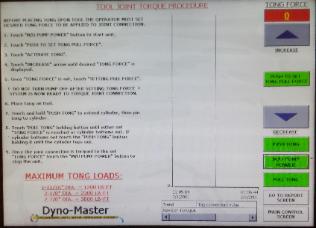

| Optional Equipment Available; Make / Break Torquing System. |

| Dyno-Master Vise System 1.69" to 3.75" Dies Available (standard equipment) |

| Dyno-Master Cross-Overs 1" MT, 1-1/2" MT, 2-3/8" PAC (standard equipment) |

| For more information please email; dyno@dyno-master.com |

PUMP SYSTEM OPTIONS (200 Horsepower) 126 GPM @ 2100 PSIG 92 GPM @ 2950 PSIG 75 GPM @ 3500 PSIG Double any of the above; (400 Horsepower) 252 GPM @ 2100 PSIG 184 GPM @ 2950 PSIG 150 GPM @ 3500 PSIG |

| The Dyno-Master system is used throughout the World by the Biggest and Smallest Coiled Tubing Motor service providers. The Dyno-Master is utilized to provide after redress, pre-run and post run motor performance verification. The Dyno-Master is also an excellent training tool for motor operators providing a visual representation of the correlation between an applied flow rate and the resultant pressure, speed and torque of the motor. Operators can apply variable loads to the motor, raising the differential pressure across the motor, producing torque and speed values that will allow the operator to be more effective when running the motor in the field. |